Eco-Friendly Industrial Cutting Methods

Advertisement

Introduction

Industrial cutting methods are essential in various manufacturing processes, ranging from metal fabrication to textile production. However, traditional cutting methods often involve the use of harmful materials and emit toxic substances into the environment. In response to the growing concern over environmental sustainability, eco-friendly industrial cutting methods have gained popularity in recent years.

These methods prioritize reducing waste, energy consumption, and pollution during the cutting process. They utilize innovative technologies and sustainable practices to minimize environmental impact while maintaining efficiency and quality. This article will explore the strengths and weaknesses of eco-friendly industrial cutting methods and provide valuable insights into their implementation and benefits.

By adopting eco-friendly cutting methods, industries can not only reduce their carbon footprint but also contribute to creating a more sustainable and environmentally friendly manufacturing sector. Let’s delve deeper into the world of eco-friendly industrial cutting methods and discover how they can revolutionize the way we manufacture products.

As consumers become more conscious of the environmental impact of the products they purchase, the demand for eco-friendly manufacturing processes continues to rise. By understanding the different methods available, industries can make informed decisions that benefit both the planet and their bottom line.

Now, let’s explore the strengths and weaknesses of eco-friendly industrial cutting methods to better understand their impact and potential for transforming the manufacturing industry.

Strengths of Eco-Friendly Industrial Cutting Methods:

Strengths

Eco-friendly industrial cutting methods offer a range of benefits that can improve efficiency, reduce costs, and minimize environmental impact. Let’s take a closer look at some of the key strengths of these cutting methods:

1. Reduced Energy Consumption

One of the main advantages of eco-friendly cutting methods is their ability to reduce energy consumption compared to traditional cutting processes. By utilizing advanced technologies and optimizing cutting techniques, industries can significantly lower their energy usage and operational costs.

In traditional cutting methods, a substantial amount of energy is required to power machinery and equipment, leading to high electricity bills and environmental strain. Eco-friendly cutting methods focus on energy-efficient practices, such as using renewable energy sources and incorporating automation to reduce energy waste.

This not only benefits the environment by decreasing carbon emissions but also contributes to long-term cost savings for industries. By investing in eco-friendly cutting methods, companies can improve their sustainability profile and enhance their profitability through reduced energy expenses.

2. Minimized Waste Generation

Another key strength of eco-friendly industrial cutting methods is their ability to minimize waste generation throughout the cutting process. Traditional cutting methods often result in significant material wastage due to inefficient cutting techniques and practices.

Eco-friendly cutting methods aim to optimize material usage and reduce waste through precision cutting technologies and automation. By minimizing scrap material and offcuts, industries can lower their raw material costs and decrease their environmental footprint.

This is particularly important in industries that produce high volumes of waste during the cutting process, such as metal fabrication and textile manufacturing. By implementing eco-friendly cutting methods, companies can improve their resource efficiency and reduce their impact on the environment.

3. Lower Carbon Footprint

Eco-friendly industrial cutting methods help industries lower their carbon footprint by reducing greenhouse gas emissions and environmental pollution. Traditional cutting methods that rely on fossil fuels and produce harmful by-products contribute to climate change and air pollution.

With eco-friendly cutting methods, companies can use cleaner energy sources, such as solar or wind power, to reduce their carbon emissions and environmental impact. By transitioning to sustainable practices, industries can contribute to global efforts to combat climate change and preserve natural resources.

Lowering their carbon footprint not only benefits the environment but also enhances the reputation of companies as environmentally responsible and sustainable. Consumers are increasingly inclined to support businesses that prioritize eco-friendly practices, making it a strategic advantage for industries to adopt these cutting methods.

4. Improved Product Quality

Eco-friendly cutting methods not only offer environmental benefits but also contribute to improved product quality and precision. By utilizing advanced cutting technologies and automation, industries can achieve higher levels of accuracy and consistency in their manufacturing processes.

Traditional cutting methods often result in uneven cuts, rough edges, and quality defects that impact the final product’s appearance and functionality. Eco-friendly cutting methods focus on precision cutting and quality control to ensure that products meet strict specifications and standards.

This results in higher-quality products that are more reliable and durable, leading to greater customer satisfaction and brand loyalty. By prioritizing quality in the cutting process, industries can differentiate themselves in the market and build a reputation for excellence and innovation.

5. Compliance with Regulations

Eco-friendly industrial cutting methods help industries comply with environmental regulations and standards related to pollution prevention and resource conservation. Governments and regulatory bodies are increasingly imposing stricter requirements on industrial processes to protect the environment and public health.

By adopting eco-friendly cutting methods, industries can ensure that they meet these regulations and avoid potential fines or sanctions for non-compliance. Sustainable cutting practices, such as waste reduction and emissions control, demonstrate a commitment to environmental stewardship and regulatory compliance.

Companies that align their cutting processes with environmental regulations not only avoid legal risks but also position themselves as responsible corporate citizens. This can enhance their reputation among customers, investors, and other stakeholders who value sustainability and ethical business practices.

6. Enhanced Workplace Safety

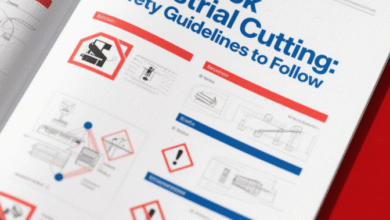

Eco-friendly cutting methods prioritize workplace safety by reducing exposure to hazardous materials and improving working conditions for employees. Traditional cutting processes often involve the use of harmful substances, such as chemicals and fumes, that pose health risks to workers.

With eco-friendly cutting methods, industries can minimize the use of toxic materials and implement safety measures to protect employees from potential hazards. By promoting a safe and healthy work environment, companies can reduce the risk of accidents, injuries, and illnesses among their workforce.

Investing in workplace safety not only benefits employees’ well-being but also enhances productivity and morale within the organization. By prioritizing safety in the cutting process, industries can create a culture of care and responsibility that attracts and retains top talent.

7. Long-Term Sustainability

Eco-friendly cutting methods contribute to long-term sustainability by promoting resource efficiency, environmental protection, and economic stability. Traditional cutting processes that deplete natural resources and pollute the environment are not sustainable in the long run.

With eco-friendly cutting methods, industries can minimize their environmental impact and preserve resources for future generations. By adopting sustainable practices and technologies, companies can ensure the longevity and resilience of their operations in an increasingly competitive and resource-constrained world.

This long-term perspective benefits both the planet and the industry by fostering innovation, growth, and resilience. Companies that prioritize sustainability in their cutting methods can adapt to changing market conditions and regulatory requirements while contributing to a more sustainable and prosperous future.

Weaknesses

While eco-friendly industrial cutting methods offer numerous advantages, they are not without their weaknesses and challenges. Understanding the potential drawbacks of these cutting methods is essential for industries to make informed decisions and effectively address these limitations.