CNC for Beginners: The Ultimate Guide to Computer Numerical Control

Advertisement

Introduction: Unlocking the Potential of CNC Technology

Computer Numerical Control (CNC) has revolutionized the way industries operate by automating processes typically done manually. For beginners looking to delve into the world of CNC, this comprehensive guide will provide a step-by-step overview of the basics, strengths, and weaknesses of CNC machines, along with helpful tips to kickstart your CNC journey.

Understanding the Basics of CNC

Before diving into the intricacies of CNC machines, it is essential to understand the fundamental concepts behind this advanced technology. CNC refers to the automation of machine tools controlled by computers to execute precise instructions. Instead of manually operating the machinery, CNC machines receive coded instructions to perform intricate tasks with accuracy and efficiency.

The Advantages of CNC for Beginners

One of the primary strengths of CNC technology is its precision and consistency in executing complex designs. For beginners, this level of accuracy can significantly reduce the margin of error in their projects and enhance the overall quality of their work. Additionally, CNC machines are versatile and can be programmed to handle various materials, making them suitable for a wide range of applications.

The Limitations of CNC for Beginners

While CNC technology offers numerous benefits, beginners may encounter challenges when first starting. The initial cost of purchasing a CNC machine can be prohibitive for some individuals, especially hobbyists exploring the technology for personal projects. Moreover, the complexity of programming and operating CNC machines may require a steep learning curve for beginners unfamiliar with this technology.

Benefits of Learning CNC Programming

Mastering CNC programming is a valuable skill that can open up a world of opportunities for beginners. By understanding how to create and edit CNC code, individuals can customize their projects, troubleshoot technical issues, and optimize the performance of their CNC machines. Learning CNC programming can also lead to lucrative career prospects in industries that heavily rely on this technology.

Practical Applications of CNC Technology

From manufacturing and prototyping to woodworking and metalworking, CNC technology has diverse applications across various industries. Beginners can leverage CNC machines to create intricate designs, prototypes, and customized products with precision and efficiency. Whether you are a hobbyist or aspiring professional, incorporating CNC technology into your workflow can enhance your creative capabilities.

Choosing the Right CNC Machine for Beginners

When selecting a CNC machine for beginners, consider factors such as the size, capabilities, and budget constraints of your projects. Entry-level CNC machines like desktop mills or routers are ideal for beginners looking to familiarize themselves with this technology without making a significant financial investment. As you gain experience and confidence, you can explore more advanced CNC machines tailored to your specific needs.

Strengths and Weaknesses of CNC for Beginners

Strengths of CNC Technology

1. Precision: CNC machines offer unparalleled precision in executing intricate designs and cuts, ensuring consistent quality in finished products.

2. Efficiency: By automating processes, CNC technology accelerates production cycles and reduces human error, resulting in faster turnaround times.

3. flexibility: CNC machines can handle a wide range of materials, from plastics and metals to composites, making them versatile for different applications.

4. Scalability: CNC technology is scalable, allowing businesses and individuals to expand their production capabilities as needed without compromising quality.

5. Customization: CNC programming enables users to customize designs and projects based on specific requirements, fostering creativity and innovation.

6. Reliability: CNC machines operate consistently and reliably, providing a stable workflow that minimizes downtime and maximizes productivity.

7. Automation: The automation features of CNC technology streamline processes, reduce manual labor, and optimize resource utilization for improved efficiency.

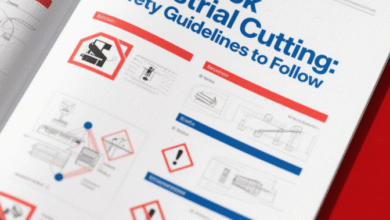

Weaknesses of CNC Technology

1. Initial Cost: The upfront investment in purchasing a CNC machine can be a barrier for beginners or small businesses with limited budgets.

2. Learning Curve: Becoming proficient in programming and operating CNC machines requires time, dedication, and continuous learning, which may be challenging for beginners.

3. Maintenance: Regular maintenance and troubleshooting of CNC machines are necessary to ensure optimal performance and longevity, which can be time-consuming and costly.

4. Complexity: The intricacies of CNC programming and machine operations may overwhelm beginners unfamiliar with this technology, leading to errors and inefficiencies.

5. Size Limitations: Entry-level CNC machines have size constraints that may limit the scope of projects beginners can undertake, requiring upgrades for larger-scale work.

6. Software Compatibility: The compatibility of CNC software with different operating systems and design programs can pose challenges for beginners looking to integrate their workflows seamlessly.

7. Technical Support: Access to reliable technical support and resources for troubleshooting issues with CNC machines may be limited, especially for beginners navigating this technology independently.

Complete Information about CNC for Beginners

| Feature | Description |

|---|---|

| Accuracy | CNC technology offers precise and consistent results for complex designs. |

| Versatility | CNC machines can work with various materials, making them adaptable for different projects. |

| Scalability | Businesses and individuals can scale their production capabilities as needed with CNC technology. |

| Customization | CNC programming allows for customization of designs and projects to meet specific requirements. |

| Automation | CNC machines automate processes to optimize workflow and resource utilization for improved efficiency. |

Frequently Asked Questions about CNC for Beginners

1. What is CNC technology?

CNC technology refers to the automation of machine tools controlled by computers to execute precise instructions.

2. What are the primary advantages of CNC for beginners?

Beginners can benefit from the precision, efficiency, and versatility of CNC machines to enhance their projects.

3. How can beginners overcome the learning curve of CNC programming?

By investing time in learning and practicing CNC programming, beginners can gradually develop proficiency in using this technology.

4. What types of materials can be used with CNC machines?

CNC machines can work with materials such as wood, plastic, metal, and composites to create a wide range of products.

5. What are the common challenges beginners face with CNC technology?

Beginners may encounter difficulties with programming, maintenance, and software compatibility when starting with CNC machines.

6. How important is scalability in choosing a CNC machine for beginners?

Scalability allows beginners to expand their production capabilities as their projects grow, making it a crucial consideration when selecting a CNC machine.

7. Where can beginners find resources for learning CNC programming?

Online tutorials, courses, and community forums are valuable resources for beginners looking to enhance their CNC programming skills.

Conclusion: Embracing CNC for Beginners

In conclusion, CNC technology offers a wealth of opportunities for beginners looking to explore the world of automation and precision machining. By understanding the strengths, weaknesses, and practical applications of CNC machines, beginners can leverage this technology to enhance their creativity and productivity. Whether you are a hobbyist or aspiring professional, embracing CNC technology can elevate your projects to new heights and unlock endless possibilities in the realm of manufacturing and design.

Take Action Today

If you are ready to embark on your CNC journey, take the first step by familiarizing yourself with the basics of CNC technology and exploring different CNC machines tailored to your needs. Invest in learning CNC programming and practicing with hands-on projects to develop your skills and unleash your creative potential with CNC technology. Remember, the possibilities are endless when you embrace the power of CNC technology!

Disclaimer

This article is for informational purposes only and does not constitute professional advice. Readers are encouraged to seek guidance from experts or professionals when working with CNC machines to ensure safety and optimal usage. The author and publisher do not assume any liability for any actions taken based on the information provided in this article.