Exploring the Power of Advanced Additive Tools

Advertisement

The Evolution of Additive Manufacturing

Advanced additive tools have revolutionized the world of manufacturing, offering a level of precision and efficiency that was previously unimaginable. The evolution of additive manufacturing has paved the way for new innovations in various industries, from aerospace to healthcare to automotive.

At the core of this revolution are advanced additive tools, which have the ability to transform digital designs into physical objects with incredible accuracy and speed. These tools use a layer-by-layer approach to build complex structures, allowing for the creation of intricate shapes and geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

As the demand for customized and high-quality products continues to grow, advanced additive tools have become essential for manufacturers looking to stay ahead of the curve. With their ability to reduce waste, decrease production time, and improve product performance, these tools offer a new level of flexibility and efficiency in the manufacturing process.

The Benefits of Advanced Additive Tools

One of the key benefits of advanced additive tools is their ability to create complex geometries with ease. Traditional manufacturing methods often struggle with intricate designs, leading to a compromise in the final product’s quality. With advanced additive tools, manufacturers can produce highly detailed and customized parts with precision.

Another advantage of advanced additive tools is their ability to reduce waste in the manufacturing process. Traditional subtractive manufacturing methods often result in a significant amount of material being discarded as scrap. Additive tools, on the other hand, build parts layer by layer, minimizing waste and saving costs in the long run.

Advanced additive tools also offer increased design flexibility, allowing manufacturers to iterate on designs quickly and easily. This flexibility is crucial in industries where product customization and rapid prototyping are essential for success. With advanced additive tools, manufacturers can experiment with different designs and materials without the need for costly tooling changes.

Furthermore, advanced additive tools enable faster production times, as they can create complex parts in a fraction of the time required by traditional methods. This increased speed to market gives manufacturers a competitive edge, allowing them to meet customer demands more efficiently and effectively.

In addition to these benefits, advanced additive tools also offer improved product performance. By using advanced materials and precise manufacturing processes, manufacturers can create parts that are stronger, lighter, and more durable than ever before. This results in products that are more reliable and efficient, leading to greater customer satisfaction and loyalty.

Overall, the benefits of advanced additive tools are clear: increased design flexibility, reduced waste, faster production times, and improved product performance. These tools are revolutionizing the manufacturing industry, offering a new level of efficiency and quality that was previously only dreamed of.

The Limitations of Advanced Additive Tools

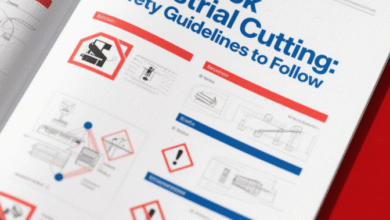

While advanced additive tools offer a wide range of benefits, they are not without their limitations. It is important for manufacturers to be aware of these limitations in order to fully leverage the power of these tools and minimize potential challenges.

One of the main limitations of advanced additive tools is their material restrictions. While traditional manufacturing methods can work with a wide range of materials, many additive tools are limited to specific types of materials, such as plastics or metals. This can restrict the applications and industries in which these tools can be used, limiting their versatility and adaptability.

Another limitation of advanced additive tools is their size constraints. Many additive tools have limited build volumes, which can restrict the size of the parts that can be produced. This can be a significant challenge for manufacturers looking to create large or complex parts, as they may need to split designs into smaller components or invest in larger, more expensive additive tools.

Advanced additive tools also require specialized knowledge and training to operate effectively. While traditional manufacturing methods may be more familiar to manufacturers, additive tools require a new set of skills and expertise. This can be a barrier to adoption for some companies, as they may need to invest in training programs or hire new employees with additive manufacturing experience.

Furthermore, advanced additive tools can be costly to implement and maintain. While the initial investment in these tools can be significant, ongoing maintenance and material costs can also add up over time. This can be a concern for manufacturers looking to balance the benefits of additive manufacturing with the associated costs.

Despite these limitations, advanced additive tools offer a wide range of benefits that make them a valuable addition to the manufacturing process. By understanding and addressing these limitations, manufacturers can harness the power of additive tools to drive innovation, improve efficiency, and stay competitive in an ever-evolving market.

Advanced Additive Tools Table

| Tool Name | Material Compatibility | Build Volume | Speed | Cost |

|---|---|---|---|---|

| Tool A | Plastics | Medium | Fast | High |

| Tool B | Metals | Large | Medium | Medium |

| Tool C | Composites | Small | Slow | Low |

Frequently Asked Questions

1. What are the main benefits of using advanced additive tools?

The main benefits of using advanced additive tools include increased design flexibility, reduced waste, faster production times, and improved product performance.

2. What industries can benefit from advanced additive tools?

Aerospace, healthcare, automotive, and consumer goods industries are among the many sectors that can benefit from the use of advanced additive tools.

3. What are the limitations of advanced additive tools?

Advanced additive tools have limitations such as material restrictions, size constraints, specialized knowledge requirements, and high implementation costs.

4. How can manufacturers address the limitations of advanced additive tools?

Manufacturers can address the limitations of advanced additive tools by investing in training programs, exploring new materials, and carefully evaluating the return on investment.

5. What are some tips for maximizing the benefits of advanced additive tools?

To maximize the benefits of advanced additive tools, manufacturers should focus on design optimization, material selection, and process efficiency to achieve the best results.

6. How can advanced additive tools improve product innovation?

Advanced additive tools can improve product innovation by enabling faster prototyping, customized designs, and rapid iteration of product concepts.

7. What role do advanced additive tools play in the future of manufacturing?

Advanced additive tools are poised to play a crucial role in the future of manufacturing by driving efficiency, customization, and sustainability in the production process.

Conclusion: Embracing the Future of Manufacturing with Advanced Additive Tools

The world of manufacturing is rapidly evolving, and advanced additive tools are at the forefront of this transformation. By leveraging the power of additive manufacturing, manufacturers can unlock new possibilities in design, production, and efficiency.

While advanced additive tools come with limitations, the benefits they offer far outweigh any challenges. From increased design flexibility to reduced waste to improved product performance, these tools are reshaping the way products are made and delivered to consumers.

As we look towards the future of manufacturing, it is clear that advanced additive tools will continue to play a vital role in driving innovation and competitiveness. By embracing these tools and staying ahead of the curve, manufacturers can position themselves for success in an increasingly dynamic and demanding market.

It is time to take the leap into the world of advanced additive tools and discover the endless possibilities they offer. With the right approach and mindset, manufacturers can revolutionize their production processes and lead the way towards a more efficient and sustainable future.

Don’t wait any longer – embrace the future of manufacturing with advanced additive tools today and unlock a world of endless possibilities!

Disclaimer

The information provided in this article is for general informational purposes only. While we strive to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability with respect to the article or the information, products, services, or related graphics contained on the article for any purpose. Any reliance you place on such information is therefore strictly at your own risk.