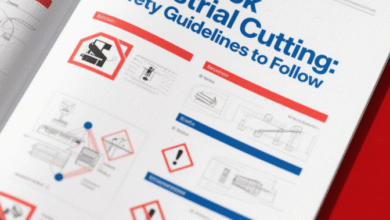

Cost Analysis of Industrial Cutting Processes

Advertisement

The Importance of Cost Analysis in Industrial Cutting Processes

Cost analysis is a crucial aspect of industrial cutting processes that involves evaluating the expenses associated with various cutting methods and technologies. By conducting a thorough cost analysis, companies can determine the most cost-effective cutting solutions for their operations, ultimately leading to increased efficiency and profitability.

Understanding the Components of Cost Analysis

Cost analysis in industrial cutting processes involves considering various factors such as the initial investment in cutting equipment, maintenance costs, energy consumption, labor costs, and materials expenses. By analyzing these components comprehensively, companies can gain a clear picture of the total cost of their cutting operations.

The Role of Technology in Cost Analysis

Advancements in cutting technology have significantly impacted cost analysis in industrial processes. Modern cutting methods such as laser cutting and waterjet cutting offer higher precision and faster cutting speeds, which can contribute to cost savings in the long run. Companies must evaluate the benefits of adopting new technologies in their cost analysis process.

Implementing Cost Reduction Strategies

Once the cost analysis is complete, companies can identify areas where cost reduction strategies can be implemented. This may involve optimizing cutting parameters, streamlining production processes, or investing in more efficient cutting equipment. By continuously assessing and refining cost reduction strategies, companies can improve their bottom-line results.

Challenges in Cost Analysis

Despite its benefits, cost analysis in industrial cutting processes can present challenges. Factors such as volatile material prices, changing market conditions, and unexpected equipment downtime can complicate the cost analysis process. Companies must adapt to these challenges and incorporate flexibility into their cost analysis strategies.

The Impact of Labor Costs

Labor costs play a significant role in cost analysis for industrial cutting processes. Companies must consider factors such as wages, training expenses, and productivity levels when evaluating labor costs. Automation and workforce optimization strategies can help reduce labor costs and improve overall cost efficiency.

Environmental Considerations in Cost Analysis

Environmental sustainability is an increasingly important factor in cost analysis for industrial cutting processes. Companies must assess the environmental impact of their cutting operations, including energy consumption, waste generation, and emissions. Implementing environmentally friendly cutting technologies can lead to cost savings and positive brand reputation.

Strengths and Weaknesses of Cost Analysis of Industrial Cutting Processes

Strengths of Cost Analysis

One of the primary strengths of cost analysis in industrial cutting processes is its ability to provide companies with a comprehensive understanding of their expenses. By evaluating all cost components, companies can make informed decisions about their cutting methods and investments. Cost analysis also helps identify areas for cost reduction and optimization, leading to improved profitability.

Weaknesses of Cost Analysis

Despite its benefits, cost analysis in industrial cutting processes has some limitations. Factors such as fluctuating material prices, market volatility, and unforeseen maintenance costs can impact the accuracy of cost analysis results. Companies must regularly update their cost analysis models to account for changing variables and uncertainties.

Opportunities for Improvement in Cost Analysis

To address the weaknesses of cost analysis, companies can explore opportunities for improvement in their cost analysis processes. This may involve implementing advanced cost tracking software, conducting regular cost audits, and collaborating with industry experts for accurate cost projections. By continuously refining their cost analysis methodologies, companies can enhance their decision-making capabilities.

Enhancing Cost Analysis Through Data Analytics

Data analytics is an emerging trend in cost analysis for industrial cutting processes. By leveraging advanced data analytics tools, companies can generate real-time insights into their cost structures, identify potential cost-saving opportunities, and predict future cost trends. Data-driven cost analysis can provide companies with a competitive edge in the market.

Cost Analysis and Competitive Pricing

Effective cost analysis is essential for establishing competitive pricing strategies in industrial cutting processes. By understanding their cost structures and profit margins, companies can set competitive prices that attract customers while ensuring profitability. Continuous cost analysis allows companies to adjust pricing strategies based on market trends and competition.

Risk Management in Cost Analysis

Risk management is an integral part of cost analysis in industrial cutting processes. Companies must assess potential risks such as equipment failure, supply chain disruptions, and regulatory changes that can impact their cost structures. By incorporating risk management strategies into cost analysis, companies can mitigate potential financial losses and ensure business continuity.

Cost Analysis and Return on Investment

Cost analysis directly impacts the return on investment (ROI) for industrial cutting processes. By accurately assessing costs and benefits, companies can calculate the ROI of their cutting operations and determine the profitability of various cutting methods. A thorough cost analysis enables companies to make strategic investment decisions that maximize ROI and long-term sustainability.

Comprehensive Cost Analysis Table

| Cost Component | Cost Analysis Details |

|---|---|

| Initial Investment | Cost of cutting equipment, installation, and setup |

| Maintenance Costs | Regular maintenance, repair, and replacement expenses |

| Energy Consumption | Electricity, fuel, and energy usage costs |

| Labor Costs | Wages, training, and workforce productivity expenses |

| Materials Expenses | Cost of raw materials, consumables, and supplies |

Frequently Asked Questions (FAQs)

1. How does cost analysis impact decision-making in industrial cutting processes?

Cost analysis provides companies with valuable insights into their expenses and helps them make informed decisions about cutting methods and investments. By evaluating costs comprehensively, companies can optimize their operations for profitability.

2. What are the key components of cost analysis in industrial cutting processes?

The key components of cost analysis include initial investment, maintenance costs, energy consumption, labor expenses, and materials expenses. Understanding these components is essential for accurate cost evaluation.

3. How can companies reduce costs through effective cost analysis?

Companies can reduce costs by identifying areas for improvement in their cutting processes, optimizing cutting parameters, investing in efficient technologies, and implementing cost reduction strategies derived from thorough cost analysis.

4. What role does technology play in cost analysis for industrial cutting processes?

Advancements in cutting technology have enhanced cost analysis by offering more efficient and precise cutting methods. Companies must assess the benefits of adopting new technologies to improve cost efficiency in their operations.

5. How can environmental considerations be integrated into cost analysis?

Companies can incorporate environmental considerations such as energy consumption, waste generation, and emissions into their cost analysis. Implementing environmentally friendly cutting technologies can lead to cost savings and sustainability benefits.

6. Why is risk management important in cost analysis?

Risk management is crucial in cost analysis to identify potential risks that can impact cost structures. By assessing risks such as equipment failure and supply chain disruptions, companies can mitigate financial losses and ensure business continuity.

7. How does cost analysis impact return on investment (ROI) for industrial cutting processes?

Cost analysis directly affects the ROI of cutting operations by assessing costs, benefits, and profitability. Companies can make strategic investment decisions based on cost analysis results to maximize ROI and long-term sustainability.

Conclusion

In conclusion, cost analysis is a vital aspect of industrial cutting processes that helps companies evaluate their expenses, optimize operations, and improve profitability. By conducting thorough cost analysis and addressing challenges effectively, companies can make informed decisions on cutting technologies, cost reduction strategies, and pricing strategies. Continuous refinement of cost analysis methodologies and adaptation to changing market conditions will enable companies to stay competitive and ensure long-term success.

Take action today by implementing cost analysis practices in your industrial cutting processes to drive efficiency, cost savings, and sustainable growth. By prioritizing cost analysis and leveraging data-driven insights, you can enhance your competitiveness in the market and achieve your business goals. Start your journey towards optimized cost management and profitability now.

Disclaimer: The information provided in this article is for educational purposes only and should not be considered as financial or investment advice. Companies should consult with industry experts and conduct thorough research before implementing cost analysis strategies in their cutting operations.